Executive Summary

PROBLEMS: Our client was trying to launch a $1 billion new product line but leadership no longer trusted the team. They had repeatedly missed deadlines, were one year behind schedule, and were resistant to change.

OUTCOME: We collected problems from the leadership, sales, engineering, industrialization, quality, assembly, and supply chain teams. Leveraging our proprietary people-first psychology techniques we won over the resistant team members and collaboratively built a predictable plan to market.

METRICS: We were able to improve their predictability from 47% to over 70%, reduce redundancies by over 50%, and accelerate their Time to Market by 6 months, saving the organization $2.5 million in operating expenses and enabling $50 million in additional sales.

Prioritized Problems

Time to Market Predictability

Changes in Scope

Faster Time to Market

The Story

The Request

We were initially brought in to teach an "Agile in Hardware" methodology, but we knew that by-the-book Agile would have caused a revolt. Many of them had fled other teams to avoid problematic "change" implementations, and were bemoaning the fact that they couldn't just be left alone to do what they had successfully done in years past.

Our Process

Our process always begins with building a list of Prioritized Problems, a single ordered list of Problems from executives, managers, team leaders, and line workers. Our guiding principle is "Simultaneously solve as many problems as possible, but do not make higher order problems worse when solving lower order problems." We share this list with everyone to help create understanding across the hierarchy and build alignment. For example, they were worried about both trust and faster delivery. So we asked, "If we could deliver the product 6 months faster, but our estimates might be off, is that okay?" Their answer was that they had heard that before, and rebuilding trust through delivering on promises was critical or else they might have to shut down the project.

List of Prioritized Problems:

"Time to Market" Predictability

Changes in Scope

Faster "Time to Market"

"Simultaneously solve as many problems as possible, but do not make higher order problems worse when solving lower order problems."

1st Quarter

Based on this list, we designed a series of experiments for them to run in 1, 2, or 4 week increments. The promise with the team was that they could define success and failure. If the experiment improved their lives, we would keep using it, but if it failed we would discard it and try something else. To establish success and failure we defined our evidence to be collected based on the prioritized problems and installed software to make collecting this evidence automatic and easy.

We started with time-tested techniques from our playbook guaranteed to deliver predictability and rebuild trust, rolling them out progressively when the team was ready instead of all at once.

We used Positive Psychology techniques like "Double Aces", Framing, and Consent to build report, increase understanding, and create allies for change among the team members.

We created personality profiles to help us better understand and communicate with individual team members.

We helped them build multiple Kanban boards that could both be used to visualize work and spotlight impediments to progress.

We introduced a process of daily collaboration.

We deployed a "1/3/1" capacity planning strategy, with 1 day per week focused on past work, 3 days focused on present work, and 1 day focused on preparing for future work.

We tackled complex, unknown tasks first before tackling easy ones.

We replaced unproductive status meetings and other activities that wasted time with focused bi-weekly review sessions with management and stakeholders.

We disbanded their functional teams (engineering, marketing, manufacturing, quality, procurement, and assembly teams) and reorganized them into cross-functional teams focused on deliverables (parts, machines, finishing lines, etc.).

and more

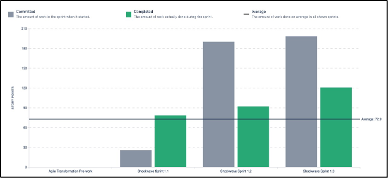

We started with their ability to be predictable week-to-week and month-to-month, gradually increasing their predictability from 45% to 60%.

2nd Quarter

Across the following three months we shifted focus to long-term predictability:

We added additional Kanban boards for long-term tasks to track completion percentages and ensure no steps were missed or skipped.

We scheduled in-person quarterly collaborative "Big Room Planning" sessions, encompassing the entire project including supporting partners and management.

We created virtual and physical prototypes for quality verification and review with stakeholders.

We used a new technique invented at OMM called Industrialization Driven Development (IDD) to map out their entire process, working backwards from sales, to assembly, delivery, quality, procurement, and design, all the way to concept engineering.

Looking back on everything we tried, the technique that had the single biggest impact on team productivity, alignment, and predictability was IDD (Industrialization Driven Development). It was not easy, but it allowed them to visualize their entire body of cross-functional work. Through it we identified 4 critical paths of work. A day-to-day slip in any of the 4 would result in a delay to final delivery. This allowed them to deprioritize non-critical work and design predictable strategies that were guaranteed to optimize the final delivery date. With their IDD Roadmap in hand, they designed entirely new strategies that initially reduced their Time to Market by 2 months, then 3-4 months, and later by 6 months.

3rd Quarter

During our last few months with the team we focused on sustainability. We made sure that the teams knew how to lead and execute on each technique without our intervention, and that they knew how to teach the techniques to new team members effectively. We also coached them through establishing their own backlog of future experiments to enable continuous growth and optimization.

By the time we left this electronics device team, we were able to improve their predictability from 47% to over 70%, reduce redundancies by over 50%, and accelerate their Time to Market by 6 months, saving the organization $2.5 million in operating expenses and enabling $50 million in potential sales.

Conclusion

"If we knew the answers to our own problems, they wouldn't be problems."

Every team is doing their best with the mindsets that they currently possess. To advance to higher levels of productivity, they need to learn new ways of thinking. In our experience, teams are capable of greater achievements, but obstacles stand in their way. Introducing a new way of thinking is a mixture of psychology and technology, but the psychological approach has a much greater impact by far. One-size-fits-all frameworks seem like a powerful quick fix, but quickly fall behind when compared to the marketing. For lasting change coaches are needed to show the teams how to "think different."